As the manufacturing industry becomes more competitive, companies must focus on delivering high-quality products while meeting stringent industry standards. For companies in the tool and stamping industry, this means adhering to IATF standards.

IATF 16949 is a global quality management standard established by the International Automotive Task Force (IATF) to ensure consistent quality in the automotive supply chain. In this blog, we will delve into the best practices and methodologies implemented by tool & Die and stamping companies to meet the stringent requirements of IATF standards.

Building Quality into the Tools and Dies

Quality is Regal Metal Products’ top priority. Our quality control system is ISO 9001 certified, and we take great pride in working with our customers through every step of the process to ensure we provide precisely what they need.

Regal Metal Products has a unique combination of engineering and manufacturing capabilities, from prototyping, engineering, and design services to tool building, metal stamping, production, and assembly. We aim to provide our customers with a fully finished part or tool ready for use in their products.

A well-designed and well-built tool is essential to achieving consistent stamping parts. This is why we expanded the company’s tool-making facility in its second plant. We can assist with product design and redesign and remake weldments, castings, forgings, and machined parts into stampings on progressive dies without sacrificing the integrity of the original item.

Regal Metal Products works with the product engineers during these projects to determine the best course of action. To assist our engineering team and customers, we maintain a large inventory of tool steels and even perform our in-house heat treating, which helps our turnaround time on new tooling and replacement parts.

The Importance of Quality Tools and Dies in Stamping

A well-built tool and die is the foundation of successful stamping operations. When a tool or die is built precisely, it can produce consistent and repeatable parts. This is essential in meeting IATF standards for quality and consistency.

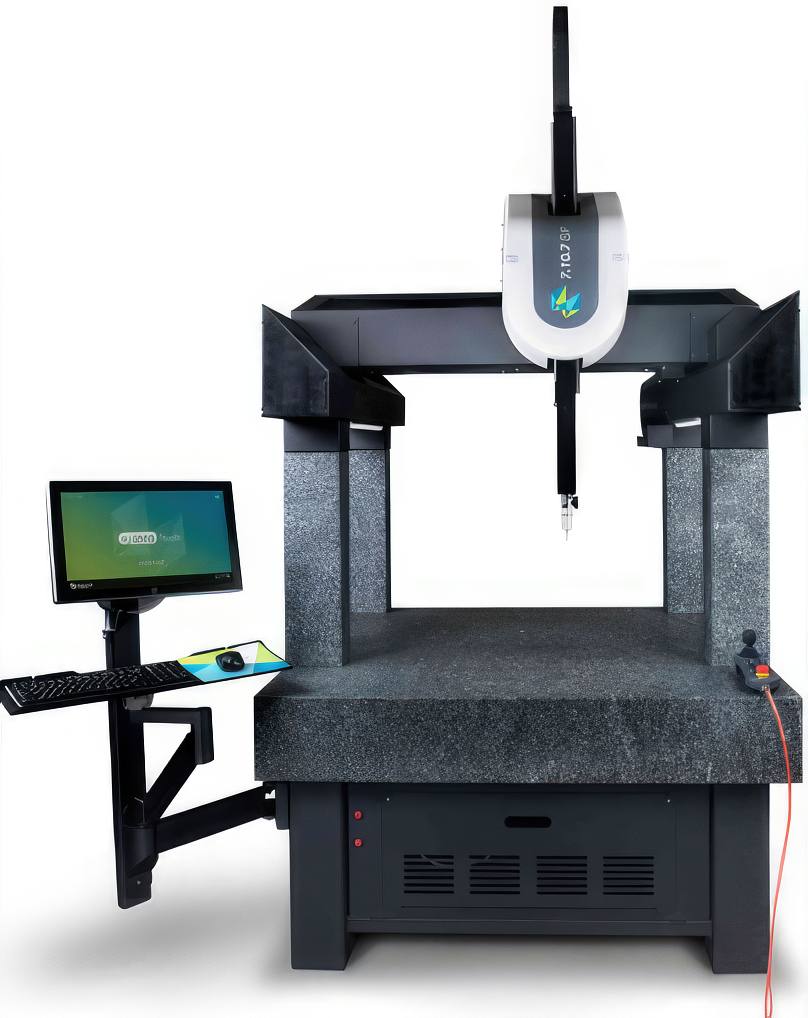

Regal Metal Products has invested in the latest technology to produce high-quality tooling. Our equipment for tool production includes two AgieCharmilles Wire EDM machines, two HAAS TL-Z CNC Lathes, Haas VF-11/50, Haas VF-3YT/50, and two large surface grinders. Having state-of-the-art equipment ensures that the tool-making process is precise and efficient.

Regal Metal Products’ Best Practices for Meeting IATF Standards

Regal Metal Products’ manufacturing and engineering processes have proven benchmark stages to help ensure that their products are delivered to specification, on time, and within our client’s budget.

We implement quality checks throughout our process to ensure the end product is delivered to the customer’s specifications and on time. This is why we have an ISO 9001-certified quality management system.

Regal Metal Products’ services include engineering, design, prototyping, metal stamping, tooling, and production/assembly. We work closely with our customers at each process step, from initial prototypes and designs to building the necessary tooling and providing stampings to meet the production schedules.

Why Choose Regal Metal Products?

Regal Metal Products is a fully integrated manufacturing company specializing in producing precision-stamped products, from prototypes to the various types of tooling for this manufacturing process.

Our unique engineering and manufacturing capabilities allow us to provide a fully finished part or tool ready for Regal to produce our customers’ products. Our investment in the latest technology ensures our products meet the strictest quality standards.

Conclusion

In conclusion, a quality tool and stamping companies must adhere to IATF standards to remain competitive. Building quality into the tools and dies is essential to consistently stamping parts. At Regal Metal Products, we have invested in state-of-the-art technology and developed best practices to guarantee our products meet the strictest quality standards.

By carefully collaborating with our clients and conducting quality checks throughout our process, Regal Metal Products ensures that our products are delivered on time and within our clients’ budgets.